Summary

Since 1975, Australian company Slade Industries has offered specialist instrumentation and calibration services to help their customers’ businesses run at optimum efficiency. The company, which operates out of Brisbane, Queensland, sees many businesses whose assets have suffered from an overreliance on factory calibration. This has led Slade Industries to promote and provide regular expert recalibration for accurate process control. For businesses that need precise and reliable servicing for vital processes such as shutdowns or turnarounds, Slade Industries can use their extensive array of calibration equipment to deliver high-quality, accurate results.

Need for accuracy & efficiency

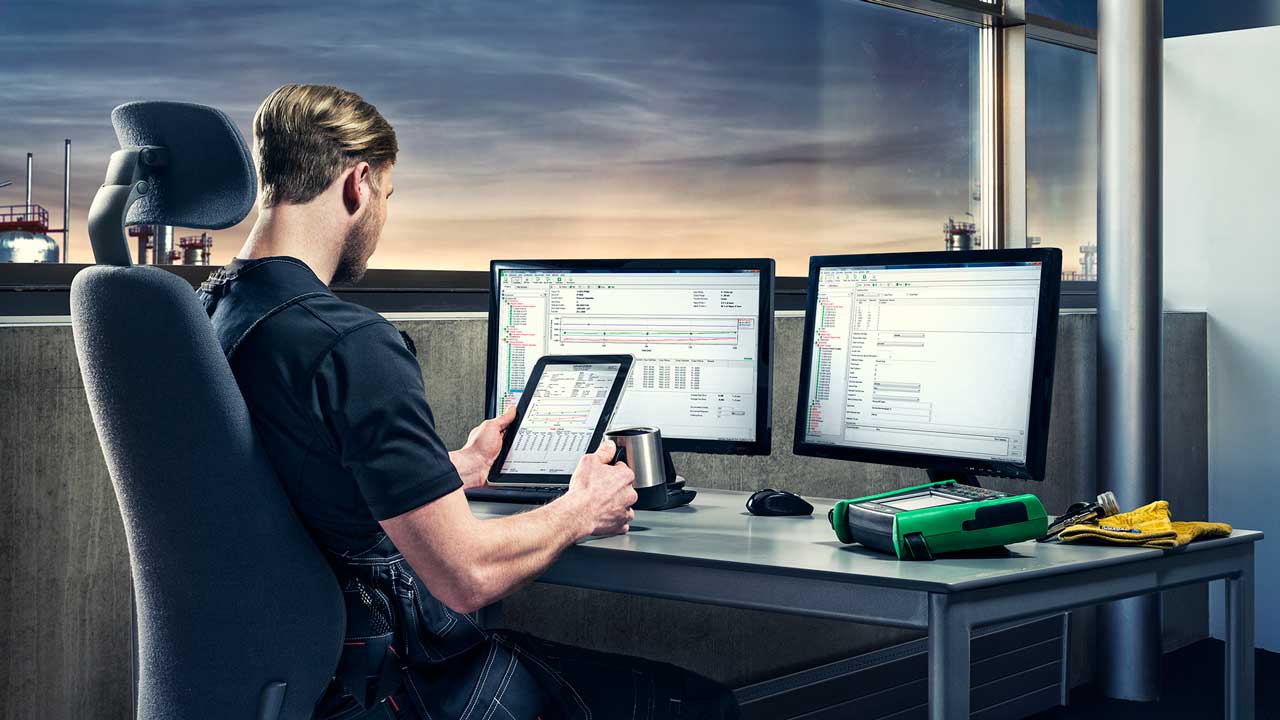

With calibration being a central part of the work carried out by Slade Industries, it is essential that their equipment provides the highest standards of accuracy and efficiency. For field calibration, we require solutions that are compact and fully functional, while still delivering efficiency and assisting with our quality assurance and control, explains Slade. The company provides complete process control instrumentation capability, so its calibration requirements are extremely broad. This is why we require process calibration equipment that can provide a range of instrumentation calibration criteria in a robust and compact solution, Slade explains.

Multifunctional equipment

We’ve found Beamex multifunction calibrators robust, easy to use, compact, and extremely reliable, Slade continues. The temperature calibrators can be used across a wide range of temperatures, sensors, and sensor sizes and can even be integrated with Beamex multifunction calibrators to provide a complete temperature calibration solution. Beamex hand pumps cover the majority of pressure ranges and can be adapted to most process connections. Finally, the CMX software ties the calibration solution together exceptionally well.

Read the full Slade Industries customer case story

No more errors

Beamex fulfilled all our requirements with a complete package including field calibrators, equipment, and the CMX software solution, continues Slade. This has helped us to execute our services more efficiently, which in turn means cost savings for our clients. We’ve also been able to eliminate data errors caused by manual data entry, including eliminating the ability to falsify a calibration result. It is very easy to download instrument calibrations to the field calibrators as well as to upload completed calibrations to the CMX system.

Accuracy, traceability & quality

Furthermore, accuracy is increased as calibration tolerances can be defined by the critical nature of the instrument function. This means that the Safety Instrument System or the instruments controlling the plant and equipment can have a tighter tolerance for accuracy. Because past calibration reports are saved in archive files, we have greater traceability for plant audits, which is extremely important to reduce liability for asset owners. Finally, the quality of service we’ve been able to provide to our clients has been noted on numerous occasions, and Beamex equipment has most certainly contributed to this, Slade finishes.