Mobile solutions – Are process industries using them right?

Sami Koskinen, Director of Digital Transformation, Beamex

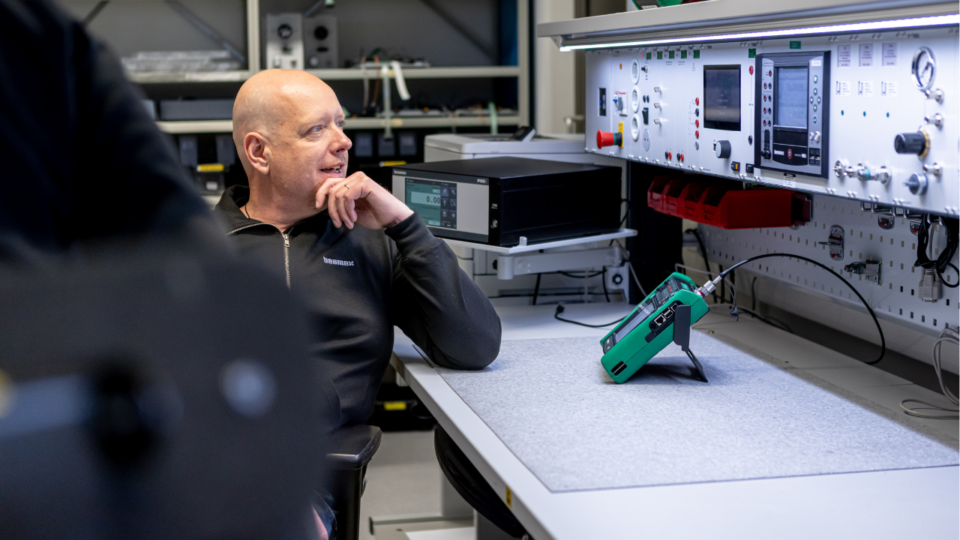

Mobile solutions are everywhere, but there are still areas where their use is restricted. These include the complex operating environments of process industries. With nearly 30 years of engineering experience, I’ve witnessed firsthand how mobility is transforming industrial operations. At the same time, we have to pay more attention to its security, durability, and design considerations to ensure mobile solutions become an asset rather than a liability.

Navigating harsh industrial environments

Industrial environments are demanding. Technicians scale ladders, troubleshoot in hazardous areas, and perform calibrations in conditions where connectivity is limited or nonexistent. Historically, they have kept calibration and measurement tools offline due to cybersecurity risks. Today, with the rise of IT and OT convergence, technicians need real-time access to monitor, diagnose, and calibrate equipment remotely, but strict regulations govern how this is done.

Explosion-proof (Ex-rated) areas (Zone 0) or highly toxic environments require mobile devices to meet stringent safety standards. Environments with hazardous air quality force workers to depend on oxygen tanks for survival. Connectivity is often restricted in such conditions to prevent ignition risks. This creates a paradox.

We rely on technology to maintain industrial systems, yet real-time connectivity isn’t an option in many cases. Mobile solutions must be able to function offline and sync data only when safe.

Many companies do not account for these constraints when designing their mobile strategies. Without toughened, safety-compliant devices, businesses risk non-compliance, safety hazards, and unreliable calibration processes. Thoughtful planning is required to ensure mobile tools can withstand extreme conditions and still provide accurate, secure data collection.

Overcoming planning and implementation hurdles

A significant challenge in mobile adoption is insufficient planning. Many plants launch operations without fully considering long-term system maintenance. I’ve seen companies invest millions in new facilities, only to realize later they overlooked calibration planning. This causes expensive manual workarounds, increases labor costs, and creates inefficiencies that could have been avoided.

The pharmaceutical industry is a prime example. Single-use sensors, made from eco-friendly plastics and burned after use, are becoming popular for modular and scalable production designs. While this addresses an environmental issue, it creates a calibration challenge. These sensors need to be calibrated before and after each production cycle, effectively doubling the workload. The problem was that calibration was not factored into the design phase. Mobile solutions need to be planned in collaboration with those who will actually use them in the field.

Failing to integrate mobile planning into industrial workflows can lead to costly setbacks. A proactive approach involves working with vendors early, identifying compliance requirements, and testing mobile tools in real-world conditions before full-scale deployment. This ensures that mobile adoption aligns with operational needs rather than disrupting them.

Addressing IT and cybersecurity challenges

A significant barrier to mobile adoption isn’t the technology itself but rather the disconnect between IT and operations. I recently worked with a client who wanted to automate a calibration process. Everything seemed straightforward. They had Beamex solutions in place, but when it came time to implement them, we hit a wall. Their IT team blocked the entire process.

The technicians knew calibration inside out, but they had no idea how their IT systems were structured. IT, on the other hand, wasn’t aware of the operational needs of manufacturing. This type of misalignment is common and often leads to costly delays. A best practice is for operations teams to engage IT early in the decision-making process. Understanding IT policies in advance prevents wasted time and ensures smoother integration.

Security is another key consideration. Strong cybersecurity measures are essential to prevent risks in industrial environments. Many companies face challenges when their mobile devices lack secure update configurations. For example, one Beamex customer wanted to add a new AI model to their mobile system, but their security policies prevented cloud downloads. To enable this, the IP addresses would need to be whitelisted.

However, opening the ports manually every time would not work if hundreds of different applications had to be opened. People need to understand these rules. If the IT department is not consulted, as in this case, a technician might not know what’s happening. Addressing IT/OT convergence challenges early can help prevent roadblocks in industrial mobility.

Cybersecurity regulations, such as IEC 62443 and GDPR, continue to evolve, impacting industrial mobility. Following these standards isn’t just about compliance; it builds trust and prevents operational risks.

The path forward

The future of industrial mobility involves not only adopting new technology but also strategic deployment. Organizations that fail to address security, durability, and interoperability issues will struggle to reap the full benefits of mobile solutions. Thoughtful planning, collaboration between IT and operations, and adherence to evolving cybersecurity standards are all critical to success.

At Beamex, we have seen firsthand how well-implemented mobile solutions can transform industrial workflows. When executed properly, mobile technology enhances efficiency, improves safety, and reduces downtime. IT/OT convergence in manufacturing ensures that mobility solutions integrate seamlessly with existing infrastructure.

The success of an IT/OT convergence strategy relies on proactive planning, security considerations, and cross-department collaboration. Industrial mobility is the future, but only for organizations that take the right steps today.

You might also find interesting

For a safer and less uncertain world

Welcome to our series of topical articles where we discuss the impact that accurate measurement and calibration has on the world and our everyday lives.