How moving OT to the cloud is redefining operational efficiency

Antonio Matamala, Country Manager, Beamex Germany

For years, industrial businesses have prioritized IT/OT convergence by bringing IT applications to the factory floor. But we’re now seeing a new trend of companies migrating operational technology (OT) software and tools to cloud platforms.

This reversal promises unprecedented scalability, streamlined maintenance, and a seamlessly integrated IT-OT ecosystem. However, will this fearless leap into the cloud unlock the next era of operational efficiency? I believe so, and here’s why.

The benefits of IT/OT convergence

IT and OT have long operated as separate domains. IT manages enterprise data and business processes, while OT focuses on physical assets and production control. Over time, IT-driven advancements like cybersecurity, analytics, and AI have made their way into OT, improving decision-making at the operational level.

However, the convergence of IT and OT is now entering a new phase, mainly through cloud-based industrial IoT systems. By centralizing OT data in the cloud, businesses can leverage powerful analytics, machine learning, and scalability. This change marks a turning point in IT/OT convergence in manufacturing, offering improved scalability by allowing businesses to handle increasing data volumes without requiring additional on-premise infrastructure.

Cloud platforms streamline maintenance by simplifying updates, security patches, and system monitoring, ultimately reducing downtime. Additionally, cloud-based analytics provide real-time and historical trend analysis, improving operational decision-making. Leading cloud providers such as Microsoft and AWS invest heavily in cybersecurity, offering protections that far surpass in-house IT systems.

Over 94% of enterprise organizations already use cloud-based solutions. Moreover, the global cloud manufacturing market reached approximately US$73.7 billion in 2023 and is projected to reach US$168.4 billion by 2028.

Barriers to cloud-based OT adoption

Despite its benefits, many organizations hesitate to move OT data into IT systems. Industry culture and historical separation deeply influence these decisions. IT/OT convergence challenges often arise due to a lack of familiarity with cloud-based solutions and concerns about security, compliance, and data ownership. OT professionals, particularly technicians, prefer an isolated, on-premise approach.

A common anxiety is the perceived loss of control. Many businesses worry about data security and regulatory compliance when sharing sensitive OT data in the cloud. However, these concerns are increasingly outdated. Microsoft alone has invested billions in cybersecurity, offering protection levels far beyond what any company can achieve in-house. Yet, convincing OT stakeholders of this reality remains a challenge.

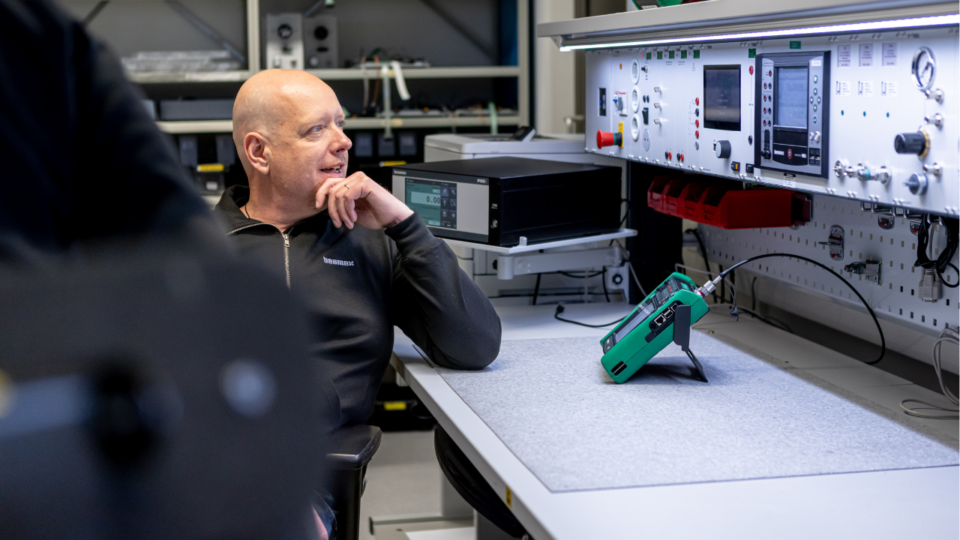

I have encountered this resistance firsthand. Beamex calibrators generate vital calibration data on the shop floor, but many customers hesitate to integrate this data into IT infrastructures. When businesses keep OT data isolated, they miss out on advanced analytics, compliance benefits, and centralized monitoring – capabilities that enhance operational efficiency and business continuity.

Furthermore, a recent survey by IDC found that 70% of manufacturers are considering or planning to adopt cloud-based Product Lifecycle Management (cPLM) in the next two years. This trend highlights the shift toward integrating OT into cloud-based platforms to better manage products from inception to completion. This transition could unlock benefits, including enhanced efficiency and real-time collaboration across departments.

A practical way forward

Successfully migrating OT data to the cloud requires buy-in from both IT and OT stakeholders. Traditionally, Beamex has engaged with OT personnel, such as calibration technicians and maintenance managers. However, to drive cloud adoption, we must also involve IT managers and business leaders as they influence broader digital transformation initiatives.

In some companies, the IT/OT divide is significant. Some actively avoid involving IT in OT decisions, fearing unnecessary complexity. However, in highly digitalized countries, such as the Netherlands, IT and OT collaboration is more seamless. In Germany, where data privacy concerns run high, I see businesses still remain more cautious about IT-led initiatives. At the same time, however, the overall trend is clearly moving toward broader cloud adoption. In recent years, Corporate IT has increasingly embraced a “cloud-first” strategy. This shift may positively influence the willingness of OT teams to adopt typical IT architectures in order to benefit from their advantages.

Rather than pushing for full-scale IT/OT integration overnight, businesses can take a step-by-step approach. Selective cloud adoption can begin with non-critical OT data, such as calibration records, before expanding to real-time production data.

Establishing buffer zones for secure integration through specialized gateways enables IT and OT environments to connect while safeguarding core systems from exposure. Leveraging AI and analytics allows cloud-based machine learning to derive insights from OT data without disrupting production environments.

Evolution of IT/OT convergence

As industries evolve, understanding the convergence of technology and its application to manufacturing is critical for future-proofing operations. Companies that adopt a strategic approach to IT/OT convergence will gain a competitive edge, ensuring they remain resilient in an increasingly digital world.

Technological advancements, particularly in AI, accelerate IT/OT convergence, unlocking vast amounts of industrial data to improve productivity, quality, and availability. The combined IT/OT market is expected to surpass US$1 trillion by 2030, highlighting the growing need for cloud-based OT integration as a driver of future success. As industries increasingly adopt these technologies, companies like Beamex play a crucial role in enabling this transformation.

This year, Beamex celebrates 50 years since its founding, marking five decades of providing innovative solutions. As the company continues to evolve, integrating cloud technologies into its solutions has become a natural next step in helping industries optimize their operations.

Companies that integrate OT with cloud technologies today will streamline their operations and set the stage for innovations that will define the future of industrial efficiency.

You might also find interesting

For a safer and less uncertain world

Welcome to our series of topical articles where we discuss the impact that accurate measurement and calibration has on the world and our everyday lives.