This is a general introduction of the Beamex CENTRiCAL Calibration and test bench solution.

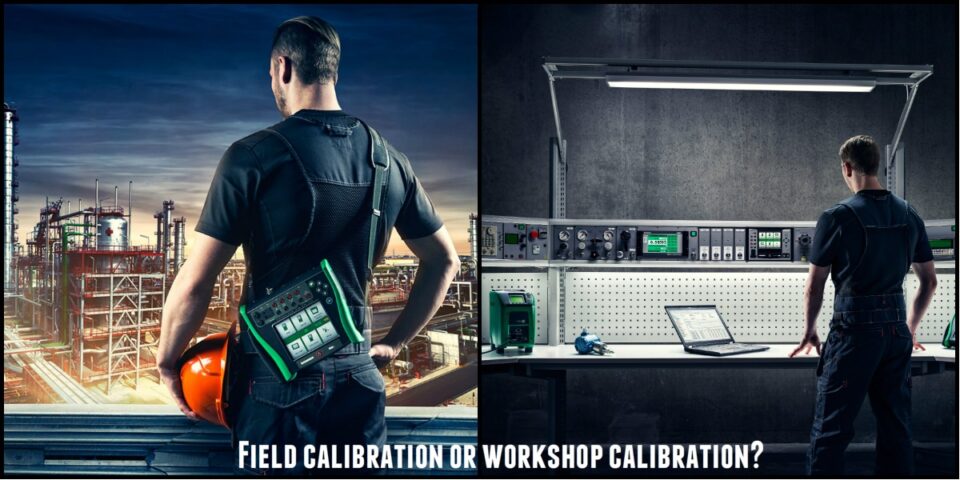

Field calibration or workshop calibration?

Sometimes the workshop calibration is more viable option. In today’s process industry, the field instruments are often calibrated out in the field, using portable calibration equipment. In some cases, the field calibration is the most suitable solution, but there are still various reasons why it is sometimes more convenient and effective to do calibration in a workshop. The best practices combine workshop calibration and field calibration. These practices are not exclusive alternatives; instead, they complement each other. Beamex offers you the best tools for both practices.

COMMISSIONING It’s a common situation that during the commissioning of a new plant or a part of the plant, the process equipment to be installed into the process have already been acquired and they are in the workshop waiting for the commissioning. With a properly equipped workshop, with all the equipment readily and ergonomically available, it is often faster and easier to calibrate the field equipment in the workshop, than using portable calibration tools. You can have your field equipment calibrated already before they are being installed.

ACCURACY / UNCERTAINTY It is typically easier to achieve a better accuracy and smaller uncertainty when the calibration is performed in the controlled environments in the workshop. Portable calibration equipment may have accuracy compromised in order to kame them small and easily portable. Workshop calibration equipment may be bigger but may also offer better accuracy. Also, the controlled environment in a workshop help to get better total uncertainty for the calibration.

ROTATIONAL SPARES It is often convenient to have rotary spare equipment for the process instruments. In case of something fails you can quickly replace it with a calibrated spare device. The calibration of spare devices is more convenient in a calibration workshop.

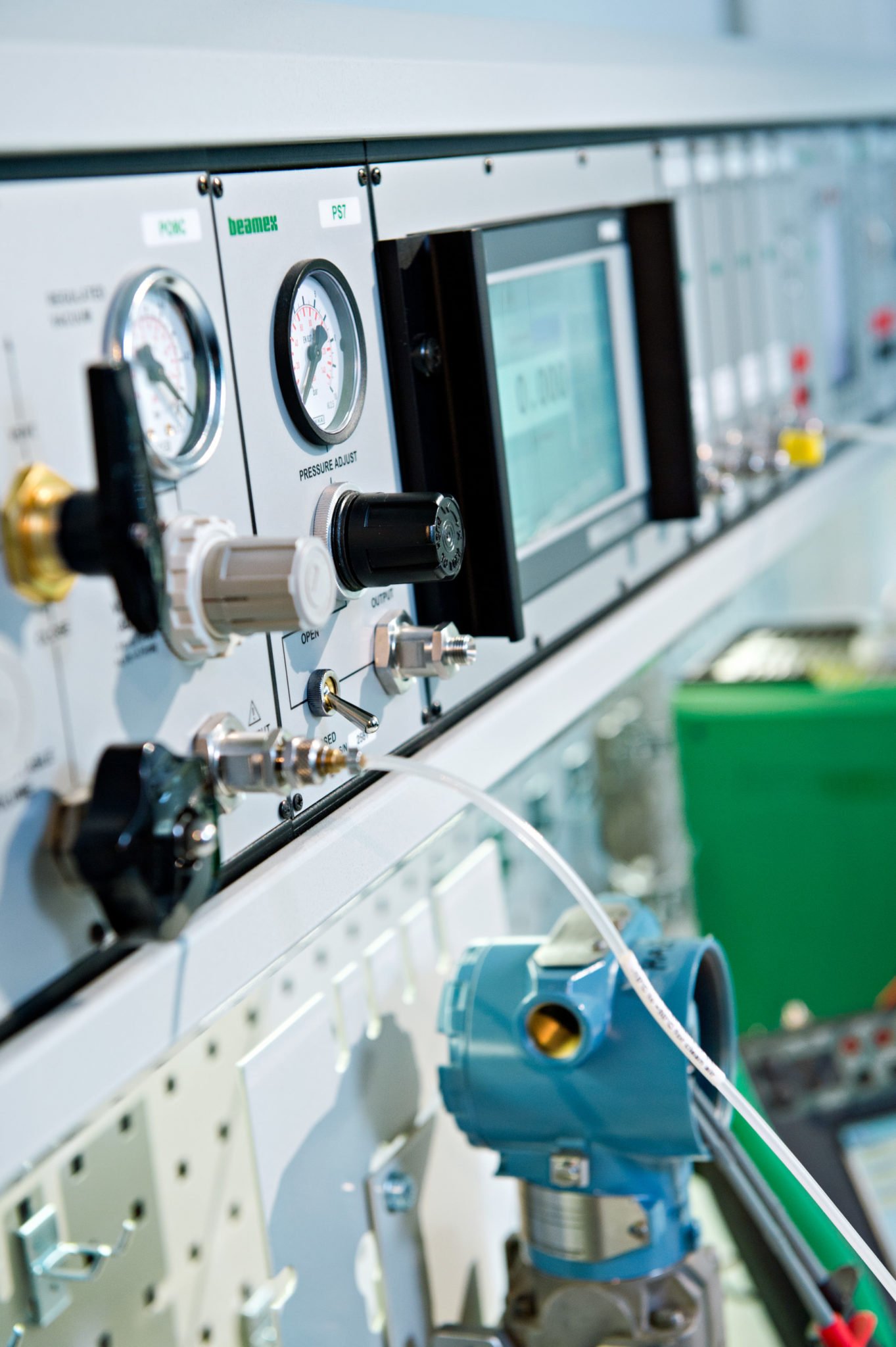

ERGONOMIC / CONVENIENT In a workshop, all necessary equipment is always in place and ready to be used. Equipment never gets lost when they are mounted on a panel. No time wasted in searching the tools needed. While workshop equipment normally runs on mains voltage, so there’s no need to charge batteries before the work. All equipment is ergonomically located in the test bench panel, with a motorized table for optimum ergonomics.

ENVIRONMENTAL CONDITIONS / SAFETY While field conditions can sometimes be very harsh to work in with extreme temperatures, humidity, dust and noise. Field conditions may also be dangerous for the workers. The workshop conditions are convenient for the worker and equipment.